All Issues

Rotator nozzles more uniform than spray nozzles on center-pivot sprinklers

Publication Information

California Agriculture 50(1):32-35. https://doi.org/10.3733/ca.v050n01p32

Published January 01, 1996

Abstract

In a comparison of Rotator and spray sprinklers on center-pivot sprinkler machines, uniformity of applied water was higher for the Rotator sprinklers. Under wind conditions, uniformity increased for the spray sprinklers and decreased for the Rotator sprinklers. Modifications to the sprinkler spacing are recommended when using the Rotator sprinklers.

Full text

Left, center pivot machines with sprinklers on drop tubes require a higher capital investment than other irrigation systems, but they can be used to irrigate frequently, have high uniformity of applied water under wind, require less labor and are easy to operate.

Center-pivot sprinkler machines are frequently used in Northern California on light- to medium-textured soils. Major advantages of center pivots are the ability to irrigate frequently, high uniformity of applied water under wind, low labor requirements and ease of operation. A major disadvantage for growers in this area is the capital cost of the machines compared to other sprinkler- and surface-irrigation systems.

Early center-pivot machines used impact sprinklers mounted on the top of the lateral with operating pressures of 60 to 80 psi. High uniformities of applied water were possible with these sprinklers because of the large wetted diameter, the rotation of the impact sprinklers and the continuous-move behavior of the machine. Spray sprinklers were later introduced. These sprinklers, which consist of a nozzle and a deflector plate, are mounted on drop tubes extending downward below the lateral to about 3 to 8 feet above the ground, depending on the system design. Water flowing downward through the nozzle is directed by the deflector plate into a horizontal spray pattern with smooth deflector plates, or into multiple horizontal jets of water with serrated deflector plates. The primary advantage of spray nozzles is the low operating pressure of 10 to 20 psi. Uniformity of these nozzles may be less than that of impact sprinklers, based on evaluations of both types of sprinklers in Northern California.

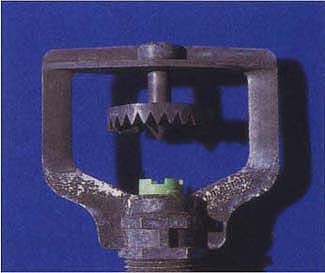

A new sprinkler, called the Rotator, has been developed by the Nelson Irrigation Company. This sprinkler design is similar to the spray sprinkler except that the deflector plate rotates, driven by the nozzle jet of water. The rate of rotation is controlled by a viscous fluid drive. The deflector plates separate the nozzle stream into one to six horizontal jets, depending on the particular deflector design. The manufacturer suggests operating pressures as low as 10 psi.

This project evaluated the performance of Rotator (use of this trade name does not imply endorsement of the product) and spray sprinklers on center-pivot machines.

Comparison of nozzles

Two center-pivot machines in adjacent fields were used for these evaluations. One machine had been converted to Rotator sprinklers; the other used spray sprinklers with serrated deflector plates. Sprinkler nozzles were pointed downward for both sprinkler types. The center-pivot machines, built by the same manufacturer, were identical with the same lateral length and same span lengths. Except for the single-sprinkler test for span 6, the machines were operated at the same travel speed for these evaluations.

We installed two transects of catch cans parallel to spans 3 and 6 of each machine. Catch-can spacing was 2 feet; can diameter was 0.5 feet. The distance between transects was about 10 feet. The length of each transect was 100 feet, centered between adjacent towers supporting the lateral pipe. The volume of water caught in the catch cans was measured after the machines passed over the transect. Evaluations were conducted under no-wind conditions and under wind conditions of about 5 to 10 miles per hour. Single-sprinkler tests also were conducted for span 3 of the Rotator machine and for spans 3 and 6 of the spray machine by plugging sprinklers on both sides of the test sprinkler. The machines were moving during the single-sprinkler tests.

Sprinkler spacings on the Rotator machine were about 20 feet for span 3 and about 10 feet for span 6. Sprinkler discharge rates were nearly 11 gallons per minute for both spans. Sprinkler spacings were about 10 feet for both spans of the spray machine. Sprinkler discharge rates were about 4 gallons per minute for span 3 and 10 gallons per minute for span 6. The serrated deflector plate of the spray sprinklers separated the flow into 26 horizontal jets. Nozzle pressures, measured with a pitot gauge, ranged between 20 and 24 psi for both machines. A pressure regulator was installed on each drop tube. Span lengths were 180 feet for both machines. Travel speed of the last tower was 2.4 feet per minute, which was 40% of the maximum speed.

Catch-can data

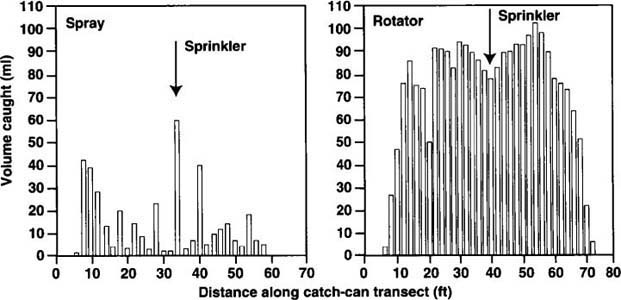

Figure 1 shows data for the single-sprinkler tests of span 6 of the spray sprinkler and span 3 of the Rotator. Wetted diameter was about 57 feet for the spray sprinkler and 65 feet for the Rotator sprinkler. Water distribution under the single spray sprinkler was highly variable, with substantial differences between adjacent catch cans. No trend or pattern was evident in the data. This behavior partly reflects both the discontinuous nature of the spray patterns caused by the serrated deflector plates and the catch-can spacing relative to that pattern. The catch-can data of the single Rotator sprinkler showed the highest volumes occurring about 10 to 15 feet on either side of the sprinkler, decreasing toward the outer edge of the wetted area. Adjacent catch cans tended to have similar volumes.

Above, the nozzle of a spray sprinkler directs water over the serrated deflector plate into multiple horizontal jets of water.

Below, the Rotator sprinkler design is similar to the spray sprinkler except that the deflector plate rotates, driven by the nozzle jet of water.

The volumes caught under the spray sprinkler were less than under the Rotator sprinkler. This was because, unknown to us during the test, the irrigator changed the travel speed of the center pivot machine to 70% instead of the 40% speed used for the Rotator sprinkler test. Less variability might have occurred at the slower speed, but a retest at the slower travel speed was not possible due to irrigator preference.

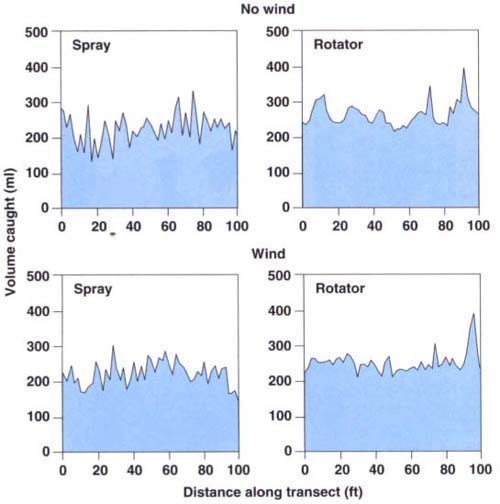

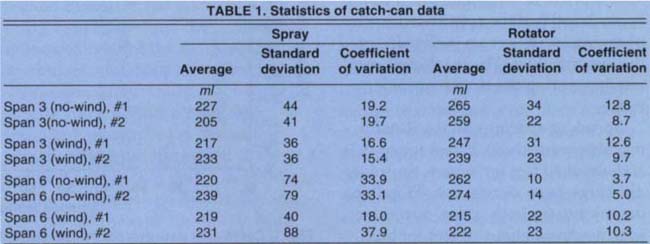

Figure 2 shows catch-can data for span 3 for transect 1 of each machine. The spray-sprinkler pattern under the no-wind condition shows considerable variability between adjacent catch cans, with relatively large volumes generally followed by a smaller volume. Volumes ranged between 140 ml and 330 ml. A similar pattern was found for the second transect under the spray nozzle. Table 1 shows slightly more water caught and a higher standard deviation for transect 1 than for transect 2. However, average volumes caught and standard deviations were statistically similar for both transects at a confidence level of 95%.

Adjacent catch-can volumes tended to be similar under the Rotator sprinklers for span 3 (no wind). A very strong periodic pattern occurred in the data of transect 1, with peak values about every 20 feet. This periodicity of about 20 feet, nearly equal to the sprinkler spacing, caused most of the variability in the catch-can data. Less periodicity occurred in transect 2. The reasons for this are not clear, but may be due to the movement behavior of the span as it passed over the transect. Average volumes of caught water were statistically similar for both transects (95% confidence level), but the standard deviations were statistically different. Transect 2 had both a smaller standard deviation and a smaller coefficient of variation than transect 1, meaning less variability in the data (table 1).

Under the wind condition, less variability occurred in the catch-can data of the spray sprinklers than occurred under the no-wind condition. Coefficients of variation were 16.6% and 15.4%, respectively, for transects 1 and 2 compared to 19.2% and 19.7%, respectively, for the no-wind condition. A pattern of high and low volumes still occurred in the data. Both average volume caught and standard deviation were statistically similar for both transects.

As shown in figure 2, wind reduced the periodic behavior for the Rotator sprinklers under span 3. However, both the standard deviation and the coefficient of variation were similar to those values under the no-wind condition. The large volumes caught near the end of the transect are believed to have been caused by water from the water jets striking a support strut.

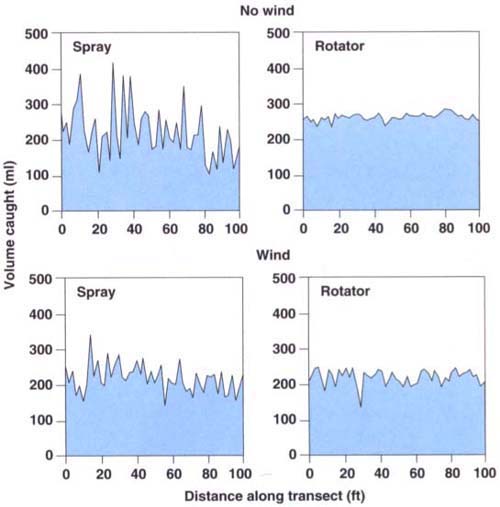

Under span 6 (fig. 3), variability in the catch-can data of the spray sprinklers under the no-wind condition was about 1.7 times greater than that under span 3. This increase in variability may reflect the faster actual travel speed of span 6 than that of span 3, although more water was caught under span 6 than under span 3 due to the higher sprinkler discharge rates. Volumes caught under span 6 ranged between 100 ml and 410 ml. High values tended to be followed by low values. Both average volume caught and standard deviation were statistically similar for both transects. Coefficients of variation for span 6 were about 33.9% and 33.1% for transects 1 and 2, respectively — nearly 42% higher than those of span 3.

In contrast, the Rotator sprinkler catch-can data under span 6 (no wind) showed a very uniform pattern (fig. 3). Variability in the data was about 12% of that of the spray sprinklers. However, average volumes caught and standard deviation were not statistically similar for transects 1 and 2, with higher values for transect 2. Both standard deviations and coefficients of variation were much smaller for span 6 than for span 3, reflecting the smaller sprinkler spacing (10 feet) of span 6. Coefficients of variation for span 6 were 3.7% and 5.0%, compared to values of 12.8% and 8.7% for span 3.

Under wind conditions, variability in the catch-can data decreased for the spray sprinklers and increased for the Rotator sprinklers (table 1 and fig. 3). However, the variability of the spray sprinklers was still 1.3 (span 3) to about 3.7 times (span 6) greater than that of the Rotator sprinklers. Variability in the catch-can data was 2 to 3 times greater under wind than under no-wind conditions (table 1) for the Rotator sprinklers under span 6; but for span 3, little differences in variability occurred between the wind and no-wind conditions. For the Rotator sprinklers, both average volumes caught and standard deviation were statistically similar for both transects under span 6. For the spray sprinklers, average volumes caught were statistically similar for both transects, but the standard deviations were not. We do not know the reasons for this finding.

The average coefficients of variation were calculated for both sprinkler types (table 1). The average coefficients were 24.2 for the spray sprinklers and 9.1 for the Rotator sprinklers, indicating that the overall variability of the spray sprinklers as 2.7 times greater than that of the Rotator sprinklers. Average values were statistically different at a confidence level of 95%.

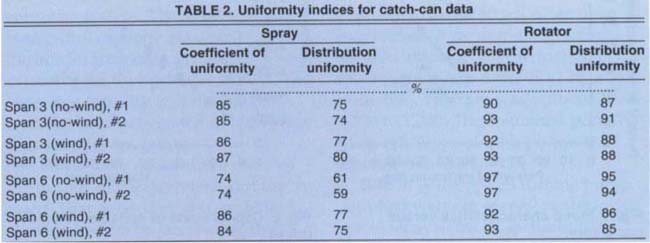

The coefficient of uniformity and the distribution uniformity are often used to describe the uniformity of sprinkler irrigation systems. The coefficient of uniformity is a statistical description that involves calculating the ratio of the average value of the absolute differences between individual catch-can values to the average value. The distribution uniformity is the minimum volume of water caught divided by the average volume caught. The minimum value is defined as the average of the lowest one-fourth of the individual values.

Table 2 shows coefficients of uniformity and distribution uniformities for both transects for each sprinkler type. Under both wind and no-wind conditions, both indices of uniformity were larger — indicating greater uniformity — for the Rotator sprinklers than for the spray sprinklers. The uniformity values were similar under wind and no-wind conditions for the Rotator sprinklers under span 3, while larger values occurred under no-wind conditions for span 6. Uniformity increased slightly for the spray sprinklers under wind conditions for both spans.

Conclusions

Sprinkler application uniformity was evaluated using catch-can data. Uniformity was found to be higher for the Rotator sprinklers than for the spray sprinklers under both wind and no-wind conditions. However, it is difficult to obtain a complete description of the spray pattern because of its discontinuous nature. The Rotator sprinkler catch-can data under span 3 (no wind) showed a periodic behavior equal to the sprinkler spacing of 20 feet. Periodicity was not obvious under wind. Little or no periodicity occurred under span 6, reflecting the smaller sprinkler spacing. Wind decreased the uniformity for the Rotator sprinklers, but increased the uniformity for the spray sprinklers.

The periodic pattern found under span 3 of the Rotator sprinklers might be reduced by decreasing the sprinkler spacing to 10 feet. However, this would require using a smaller sprinkler discharge rate of 5 gallons per minute, compared to the existing rate of 10 gallons per minute, to maintain the same application rate.

Center-pivot irrigation systems are recognized for their potential to apply water at a high uniformity compared to other sprinkler systems. The data presented in this article indicate that the Rotator sprinklers can provide high uniformity under center-pivot irrigation.

Although this evaluation was conducted on center-pivot sprinkler machines, we feel that the results also apply to linear-move sprinkler machines. However, based on these evaluations, sprinkler spacings should not exceed 10 feet.