All Issues

With a ban on burning, incorporating rice straw into soil may become disposal option for growers

Publication Information

California Agriculture 47(4):8-12.

Published July 01, 1993

PDF | Citation | Permissions

Abstract

The traditional burning of rice straw, after harvesting rice, is being phased out in California's Sacramento Valley under a 1991 state law, and rice growers are faced with seeking other ways of disposal. One option, incorporating rice straw into the soll, will require farmers to carefully evaluate the methods available to them, given their equipment holdings. In general, growers will incur much higher costs to incorporate rice straw, compared with burning it.

Full text

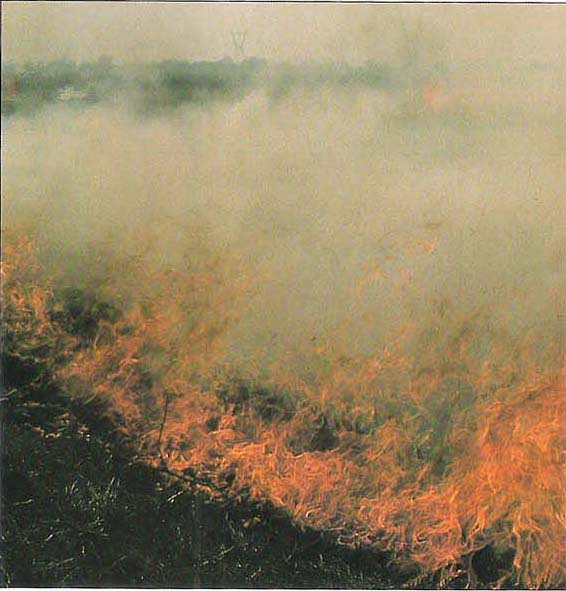

California's rice growers have three methods for disposing of the straw and stubble residue remaining in their fields after harvest: burn it, bury it or bale it. Burning, the principal disposal method for most of the industry's 80-year history, is efficient, effective and cheap, but it is being phased out in the Sacramento Valley under the Rice Straw Burning Reduction Act of 1991 (AB1378). Beginning with a 10% reduction in 1992, rice straw burning will be banned by the year 2000. A “safe harbor” clause allows burning of up to 25% of the acreage after the year 2000, if it can be demonstrated that disease harbored in the rice straw is causing crop loss.

Theoretically, rice straw can be used for many products, but today few markets are available to use it. Therefore, as burning phases out, California rice growers are likely to find as their main alternative soil incorporation, utilizing current farm implements and, as necessary, new ones to bury this high-volume, fibrous crop residue.

This article compares the costs of rice straw incorporation with burning. Only costs associated with field processing and/or disposal of straw are presented. Costs of harvesting and soil preparation, for example, are not included. Once costs have been explained, impacts of the various methods of soil incorporation are discussed, along with ideas on the methods most viable for farmers, economically and agronomically.

Rice straw management

Various choices exist among the three methods for disposing rice straw. Which is most advantageous depends on the time of year disposal occurs, the weather, the condition of soil and straw, and equipment availability and ownership. The “best” approach will depend on several factors.

Burning

Burning takes place in fall or spring. In fall, the fuel usually carries the flame better, resulting in more complete burns. Stubble does not burn completely if the burn occurs before a frost. In spring, the fuel is packed against the soil. Burning takes more time and labor, and is often incomplete. It can be carried out by workers, on foot or in vehicles, using a simple hand-held torch. Torches may also be mounted on wheels and pulled behind a vehicle. Levees may be mowed, if weed growth is tall and green, so that the flame carries over and consumes the growth. In most counties, permits are required at a small cost. Fire safety equipment is usually kept nearby.

Removal

Straw removal can involve raking loose straw, baling it in small bales and roadsiding the bales, or custom hiring the entire operation. For example, straw cut low from the combine and left in a windrow may simply be baled and hauled. However, some growers may choose to swath the stubble, thus generating more tonnage of baled straw but at a higher total cost (for removal and storage). More complexity in removal methods will evolve as the bale format (round, square, large or small, etc.) is determined by end use.

In the future, straw removal costs may be offset by revenues received from sale of the straw. Possible uses of rice straw range from bedding in horse stalls and chicken coops to serving as an ingredient in bricks, wallboard and other building materials.

Soil incorporation

Two major approaches to mixing rice straw into the soil are evolving. In the first, the straw is mixed into relatively dry soil with conventional plows, discs and tillers. In the second, the straw is pressed and poked into wet soil using specialized “cage rollers.” Although they differ, these systems share common management principles. For example, fall incorporation is better than spring because more time is available for straw to break down. Also, in each system thorough mixing of soil and straw is essential, uniform spreading helps avoid fouling of tillage equipment and improves results, and chopping the straw makes other operations easier and more effective.

On as much as 70% of California's rice acreage, rice is produced in the same field year after year. Changing this continuous production system presents special difficulties for farmers incorporating straw, who must cover the cost of incorporation with another wet-soil, short-season, high-volume, low-intensity crop. Crop rotation, where it is economically attractive, offers more flexibility in straw management than does rice monoculture and may become more common.

The cost study

California rice growers need basic information to estimate the costs of straw incorporation. In the “Results” section that follows, estimates are presented for six incorporation options to illustrate the range of costs. For each option the costs of using different combinations of equipment to perform various tasks are presented.

To calculate the cost of incorporating rice straw, many variables were considered, including the time of incorporation (spring or fall), the equipment likely to be owned by a rice farmer and information on how incorporation would fit into a year-round farming system.

Costs per acre to operate different pieces of equipment for each option were calculated with “Budget Planner,” a computer program designed by and available from the University of California's Cooperative Extension Service at Davis. (Contact Dr. Karen Klonsky at 916-752-3563 or at Agricultural Ecoomics Department, University of California, Davis, California 95616.) Budget Planner calculates costs based upon 1990 standards set by the American Society of Agricultural Engineers. The practices described are based on observations and ongoing research by county farm advisors in Northern California's rice-growing regions. Sample costs given for labor, materials, equipment and contract services are based on 1992 figures. The range of options available to rice farmers may not be applicable to every farm situation. Assumptions and data used to determine the costs per acre are outlined below.

Farm characteristics

In this study, cost comparisons were based on a 400-acre rice farm that used a rice/rice cropping system and incorporated rice straw in the fall immediately after harvest. No other crops were grown. This assumption led to results typical for the majority of rice growers in Northern California; the cost basis was different for smaller versus larger farms.

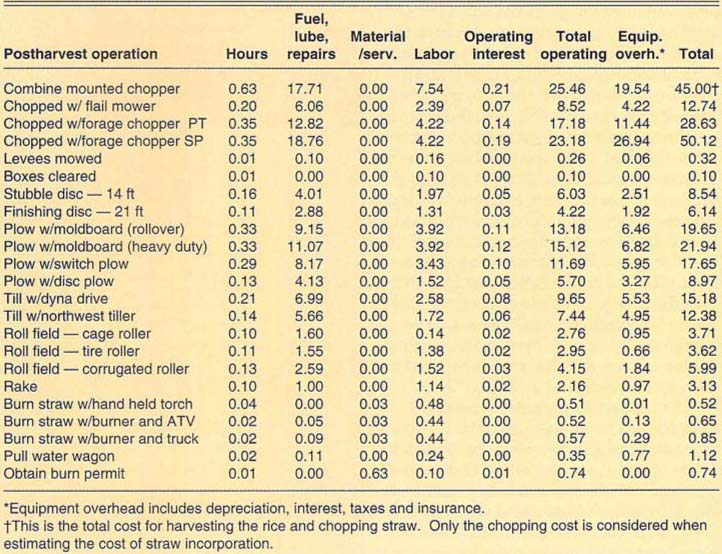

Equipment

Table 1 presents the costs per acre to complete each operation necessary. It is assumed that some equipment is new and some is used to represent the mixture found on most rice farms. In estimating equipment costs per acre, the following calculations were made: (1) Original cost of equipment is the cost of the new equipment plus sales tax. (2) Depreciation is straight-line with a 10% salvage value. (3) Interest on investment is calculated as the average value per acre of the equipment (the total value of equipment used divided by the number of acres) during its useful life, multiplied by a real interest rate of 4%. (4) The actual hours used represent only those hours devoted to rice straw incorporation. Allocation of costs, however, was based on the total number of hours the equipment is used all year.

Labor

Basic hourly cost for farm machine operators and field workers was calculated at $7.46 an hour. Adding 34% for Social Security insurance and other benefits increased the labor rates shown to $10 an hour for machine operators and field workers. Labor hours for operations involving machinery are estimated to be 10% higher than machine hours to account for extra labor involved in setting up equipment, moving it, maintenance and repair.

Fuel and repair

The fuel and repair cost per acre for each operation were determined by multiplying the total hourly operating cost for each piece of equipment by the number of hours per acre for the operation. Prices for on-farm delivery of diesel and gasoline were 71 and 98 cents per gallon, respectively.

Results

Growers are presently field testing and evaluating alternative straw management practices. In this section, estimated costs are the focus, yet some of the long-term agronomic impacts of straw incorporation may partially offset these costs, as explained in the last section of this article.

Sample rice straw disposal costs

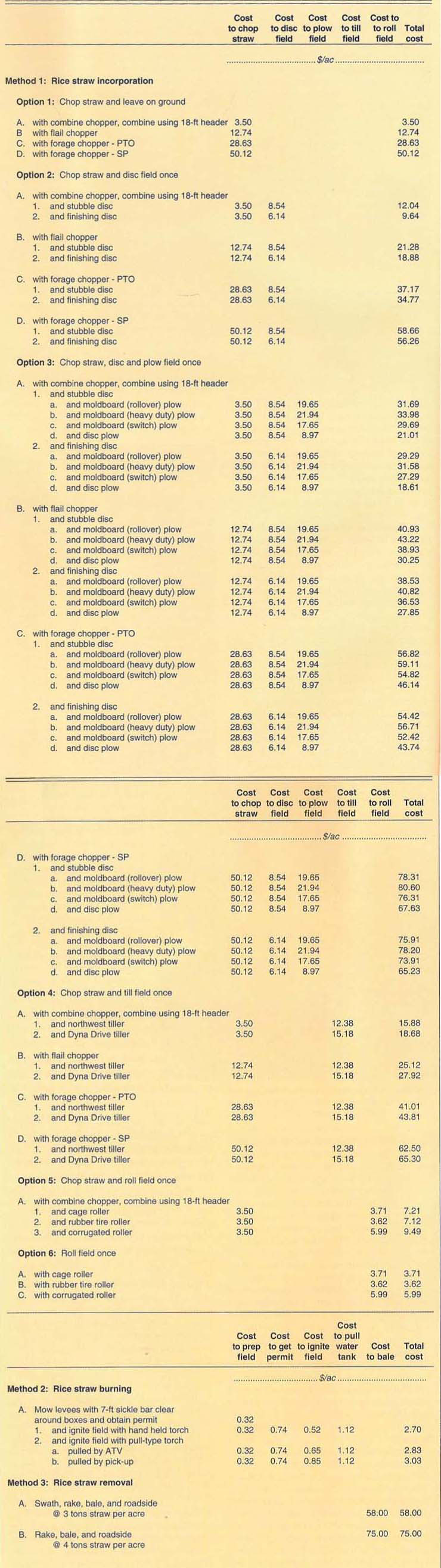

Table 2 presents total (fixed and variable) cost estimates for the three different methods available to farmers to dispose of rice straw. In the first method, the straw is incorporated into the soil; table 2 shows six options for incorporating rice straw. The first four options are for use in dry fields; the last two are for wet fields. The first column presents each option and the equipment required to complete each operation. Each option presented is a complete and separate procedure. For example, Option 2 is to chop the straw and disc the field; Option 3 is to chop the straw, disc the field and then plow it. Cost per acre for Option 3 includes the costs per acre for Option 2 plus the additional costs of plowing. Columns 2 through 6 contain the costs per acre to complete each operation. The final column shows the total cost to complete each procedure.

The total costs per acre to complete each operation are the sum of all equipment ownership and operating costs (table 1, last column), except for the costs of using the combine-mounted chopper. Since the rice would be harvested and the straw chopped at the same time, only the additional costs of using the chopper are presented. The cost of the chopper was calculated by multiplying the total costs per hour to use the rice chopper by the number of hours needed to harvest 1 acre (table 1, first column).

To compare, for example, the cost of chopping rice straw using a combinemounted chopper and discing it into the field with a stubble disc versus the cost of chopping the straw using a combinemounted chopper and tilling it into the field with a Dyna Drive tiller, see Option 2-A-1 and Option 4-A-2. Option 2-A-1 costs are $3.50 to chop the straw plus $8.54 to stubble disc the field; total cost per acre is $12.04. Option 4-A-2 costs are $3.50 to chop the straw plus $15.18 to till the field; total cost per acre is $18.68.

To place incorporation costs into context, table 2 also shows the costs of rice burning and removal. The net costs of straw removal will be lower than reported here if a market for rice straw develops; revenues received would offset costs and could possibly generate a positive cash flow for growers. Although some reports of rice straw sales have been circulated, it is premature to judge whether a stable market will develop and at what price levels.

Cultural practices

In the first incorporation method the straw is chopped and left to decompose on the ground. The straw can be chopped by a rice straw chopper attached to the rice combine so that harvesting and chopping can occur at the same time or, after harvesting, the straw can be chopped with a flail or forage chopper. In the case of the combinemounted chopper, only the additional cost of the chopper is presented.

The cost study looks at incorporation in both dry and wet fields. Under dry field conditions, which occur after harvest but before rains flood the field, there can still be residual moisture in the soil. Wet field conditions exist when rain or irrigation water is standing in the field, and the only chopping of straw possible occurs while the grain is harvested, because it is assumed that farmers tend to cut down on the amount of equipment they pull through flooded fields.

The additional costs for field flooding after the straw has been incorporated have not been included for two reasons: (1) Water costs in rice-growing areas vary considerably, from a low of $2.85 per acre-foot to a high of $75 per acre-foot, depending on the district supplying the water and whether a farmer uses pumped water. (2) For an individual farmer, flooding costs are a constant additional cost and are not influenced by the incorporation or burning of rice straw. This study seeks to examine the variations in costs to dispose of rice straw only. However, field flooding is an additional option available to farmers to facilitate rice straw decomposition.

In this study it is assumed that custom harvesters would be hired to remove straw from the field, if the third straw disposal method is chosen. This reflects the facts that presently there are few options for disposing of rice straw and farmers have not invested in the specialized equipment needed for straw removal. Costs for removing rice straw include swathing, raking, baling and removing the bales from fields for roadside pickup.

Agronomic effects of incorporation

The four goals of rice straw incorporation are to (1) minimize net costs, (2) maximize decomposition during winter, (3) minimize disease risk and (4) avoid yield loss the following growing season. Each incorporation option can lead to differences in agronomic effects on net costs; thus, it is not appropriate to assume that more costly incorporation options are inferior to less costly approaches. It is possible that more costly incorporation options have more beneficial agronomic effects than less costly options and, therefore, may have a higher net profit. As shown in table 2, incorporation costs vary greatly, depending on how the rice straw is processed and the equipment used.

In this study, costs for rice straw incorporation go from a low of $3.50 per acre to a high of $80.60, depending upon the amount of labor and equipment used. Costs for burning rice straw are about $3 per acre. The cost to remove rice straw is between $58 and $75 per acre (ignoring revenues that may be received from sales of straw).

The decision concerning the method to use depends on agronomic, as well as economic, considerations. For example, in deciding which implement to use to incorporate the straw, field and soil conditions influence the choice. Options involving discing, plowing and tilling should be used under dry field conditions; options involving rolling should be used in wet fields. Therefore, while rolling a field with a cage roller is approximately $7.21 per acre and discing the field with a stubble disc is approximately $12.04 per acre, rolling the field while it is dry will not efficiently incorporate the straw. Conversely, discing a wet field is impossible. Also, the long-run agronomic effects must be considered. As one grower explained, he did not favor “wet” methods because “mixing straw and mud is the recipe for adobe bricks” and he questioned the effects on soil condition over time.

Another critical agronomic consideration is to choose a method for chopping straw that will result in spreading the straw as uniformly as possible. One major problem associated with rice straw incorporation is that insufficient decomposition of the straw before planting of the spring crop can produce gases toxic to the plants and can cause problems later with nitrogen use by the plants.

Finally, decomposition is aided by obtaining as much contact between the straw and the soil as possible. The more the field is cultivated in the fall, the greater the degree of straw decomposition that will occur by spring. However, as shown in table 2, the more a field is cultivated, the higher the costs.

Agronomic factors have economic effects that determine the incorporation methods selected; these, in turn, influence the season's total cultivation costs. For example, research shows that when straw is completely decomposed in the soil, nitrogen is released and this can result in lower fertilizer costs the following spring. This type of effect is not included in the results presented in table 2. Also, to the extent that a particular incorporation procedure leads to a lower (or higher) yield per acre of rice in the following crop season, compared with the yield expected had the straw been burned, the lost (increased) revenues from that rice crop must be added to (subtracted from) the cost-per-acre estimate reported here for that procedure. Therefore, after agronomic effects are considered, the net cost for each incorporation method could be higher or lower than the estimate here; however, until all relevant agronomic research is completed, the exact costs of particular incorporation procedures can only be estimated.

Conclusions

This article reports the costs associated with different methods of disposing of field residue, using rice straw as a case study. Producers of other crops can follow these procedures to perform their own analysis and/or use the cost estimates presented here.

For rice growers, the decision concerning which soil incorporation method to use depends on agronomic and economic considerations. In general, rice growers incur much higher costs when incorporating their straw, compared with burning it. However, the U.S. Agricultural Stabilization and Conservation Service has a program (Special Practice 56 — Rice Residue Management) offering $25 per acre to participating farmers who do not burn their straw. Thus, the short-term effects on net profits can be reduced for program participants. Also, the significant differences in cost per acre among specific methods of straw incorporation should be viewed as an incentive for farmers to evaluate carefully the methods available to them, given their equipment holdings.

In the long term, growers may be able to further reduce and possibly eliminate net residue disposal costs by developing markets for the residue. If rice straw, for example, proves to have uses on or off the farm, growers will view the straw as a valuable by-product of rice production, rather than as the source of additional production expenses.